When simulating yagi antennas with NEC2, NEC4 or OMNEC one typically uses the bulk conductivity of the element material as one of the input parameters to the simulation program. This is well justified for new (uncorroded) elements that are mounted on a non-conducting boom tube but it is not self-evident that a real antenna that has been used for several years will have as small losses as predicted by the simulations.

There are several mechanisms by which element losses may increase above the values computed by the modelling software.

-

Reduced surface conductivity due to corrosion.

-

Ohmic losses due to Eddy currents in the boom tube or other

conducting materials near the element center.

-

Magnetic losses in washers, screws and other magnetic materials

near the element center.

-

Dielectric losses in surface coatings used to prevent corrosion.

- Dielectric losses in plastic plugs at the element tips.

Element losses are particularly important at the highest frequencies where yagi antennas are used for space communication because the sky temperature is very low. Very low system noise temperatures may be reached and a small loss in the antenna would therefore give a much larger loss in receiver S/N because besides loss of signal the ohmic losses would increase the system noise temperature since the losses would occur at room temperature. The lowest sky temperature at 500 MHz is around 15 K and modern low noise amplifiers may also have a noise temperature of 15 K. The antenna is not perfect so some noise will be picked up through sidelobes. This might add another 15 K. The ohmic losses could be 5% which would add another 15 K (5% of 290K.) If the ohmic losses are increased by 25% due to ageing or some other effect, the antenna losses would become 7.5%. The loss in gain would be 0.1 dB only, but the contribution to the system noise would increase from 15 K to 19 K which would change the noise temperature from 60 K to 64 K, causing the noise floor to increase by 0.3 dB for a loss of S/N of 0.4 dB.

A yagi that is optimised for maximum gain might have 10% ohmic losses and would be more sensitive to increased element losses. The signal would loose 0.2 dB for a 25% increase of the ohmic losses but the noise temperature would go from 75K to 82.5K causing the noise floor to increase by 0.4 dB for a total S/N loss of 0.6 dB.

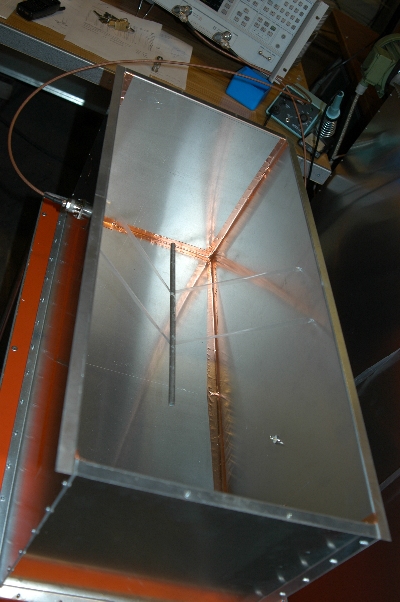

In order to get an idea of the magnitude of the additional element losses that might be introudced by the phenomena listed above we have measured the Q-value of rods inside a cavity with dimensions 0.7m x 0.3m x 0.3m, see figure 1. The elements were hung in thin polyethylene bands at the center of the box and RF energy was loosely coupled to the ends of the elements from coaxial connectors in the box wall having a small wire to give some capacitive coupling. This way the cavity with connectors and an element forms a coaxial filter and the insertion loss was set to be 40 dB or more in order to have a negligible influence on the Q-value from loading by the signal source or detector. (A network analyzer was used for both.)

Figure 1. The 0.7m x 0.3m x 0.3m box with the lid off showing a 10 mm element in position for measuremeny of the Q-value. |

Losses due to corrosionOne series of measurements was made on three different corroded elements and a new one. Figure 2 shows what the elements look like. |

Figure 2. Four elements used to measure the effects of corrosion. From top: First, new element from alloy 6063-T6 with epoxy filled polyamide element holder and non-magnetic stainless screw. Second(CO1), element used 20 years near Stockholm. Third,(CO2), element from start of regular TV in Sweden. Made from folded sheet metal, about 50 years old. Fourth,(CO3), element used on the chimney of a house that was heated with a gas burner for 10 years, then with an oil burner for 5 years. The element 38 years old but has been kept indoors the latest 25 years. The alloy is SM 5050-18, bought from Svenska Metallverken in 1967. Nowadays known as SS 4007 or 1050A. |

|

Since one of elements is from an old antenna it is not known what

alloy it is made from.

Resistivities are available for 5050 alloys but what 5050-18 means

is unknown to us.

It is easy however to measure the bulk resistivity from the resistance,

length and weight under the assumption that all the aluminium rods have

the same density 2.69 g/cm3.

The resistance was measured with a DC current of about 20 A applied at the

ends of a rod and with a millivoltmeter connected to two points a few cm

away from the ends.

The results are shown in table 1.

|

Element Total Weight Area Current Voltage Res. Dist. Resis- Diam Q-value

length (milli- for U tivity in box

(mm) (g) (mm2) (A) (mV) ohms) (mm) (ohm-cm) (mm)

New 310.8 26.10 31.22 22.64 6.55 0.2893 278 3.25E-8 10 8250

CO1 307.1 22.72 27.50 23.57 8.05 0.3415 275 3.41E-8 10 7900

CO2 307.4 17.44 21.09 24.38 10.21 0.4188 273 3.74E-8 9.6 5576

CO3 310.2 18.21 21.82 23.76 9.54 0.4015 276 3.17E-8 8 5926

Table 1. Evaluation of bulk resistivity of old elements and observed

Q-values. (The new element without element holder.)

|

|

The new element was made from alloy 6063-T6 and according to manufacturer

specifications the resistivity should be 3.30E-6 to 3.50 ohm-cm

for extruded tubes.

Cast material (heat sinks) from 6063-T6 has higher resistivity,

typically 5.3E-6 ohm-cm.

Directly from the Q-values we see that two of the corroded elements have much higher losses than the new element. The Q-values observed with elements in a box are affected by the losses of the box and not only the losses of the element itself. For an evaluation of the magnitude of the losses due to corrosion, see below. Losses due to protective coatingsLosses due to corrosion might be neglected in good locations but corrosion may be much faster in industrial areas or near salt water and therefore it might be a good idea to protect the surface with some kind of coating. Anodization is the obvious choice for aluminium so we have measured the Q-value of several anodized elements with oxide thicknesses 15u and 30u. We also checked the Q-value for painted elements (100u powder coating, polyester, Interpon 610 from Akso Nobel, product code MW701D Silver, RAL9007.)Typical values are shown in table 2. |

Q-value for element inside box. Coating diam=10mm diam=6mm diam=4mm None 8250 5480 4070 Oxide 15u 7825 5315 3908 Oxide 30u 7663 5145 3748 Paint 100u 6272 3846 3026Table 2. Q-values inside box for different coatings on aluminium. |

|

Anodization with 15u has a small but clearly visible influence on the element losses. The effect is similar to using an unprotected aluminium surface for 20 years in a good environment. The values in table 2 are typical values that do not take small variations of diameters into account. For a detailed evaluation of losses due to surface coatings, see below. Losses due to mounting materials and boom tubeElements can be mounted through the boom tube with isolators or in contact with the boom tube. Elements in contact with the boom tube should have be in very good metallic contact because of the low impedances and very high currents that cause small contact resistances to give high losses. For metallic contact welding is preferred.Elements that are mounted through the boom tube with isolators can be kept in place with Starlock washers as illustrated in figure 3. |

Figure 3. Isolated through hole mounting with Starlock washers. |

|

With isolated through-hole mounting there are Eddy currents in the boom tube that lead to a reduced Q-value. The Starlock washers are made from magnetic stainless steel and add magnetic losses. When elements are mounted on top of the boom tube in metallic contact or at a small separation from it on an insulator losses also occur. Table 3 shows Q-values for elements mounted on short boom tubes measured in the 0.7m x 0.3m x 0.3m box. The boom tube used for table 3 was a 25x25 mm tube with quadratic cross section. |

Q-value for element on boom tube inside box. Mounting on boom diam=10mm diam=6mm diam=4mm None 8250 5480 4070 Through, glued. 5700 4525 3295 Through, Starlock. 3250 2875 2120 9mm above, polyamide 6650 4407 -Table 3. Q-values inside box for different mounting methods. New aluminium elements without surface coating on 25mm x 25mm quadratic boom. The "polyamide" mounting block is visible in figure 2. |

|

Through-hole mounting with Starlock washers gives rise to severe losses on 413 MHz. Such mounting is also not compatible with anodized elements. Mounting elements at some distance from the boom tube even on a material with poor RF properties (and excellent mechanical properties) is much better for losses and compatible with anodized elements. When a 10 mm element is mounted through the boom tube one has to drill a 12 mm hole while the plastic block is well secured through a 4 mm hole. This allows the use of a slightly thinner boom tube which reduces Eddy current losses and wind load. The total losses due to surface coating and mounting to the boom tube can be expressed as an effective resistivity and included in the optimization procedure for yagi antennas. The next paragraph describes how we extract the effective resistivities from the measurements described above. Converting Q-values inside a box to effective resistivitiesIt is not self evident how to estimate how the losses of the box affect the observed Q-values, and therefore we have measured the Q-value of elements made from copper, aluminium and brass with several different diameters inside the 0.7m x 0.3m x 0.3m box. Some of these elements were also measured in a smaller box, 0.5 m x 0.3 m x 0.3 m which produces somewhat lower Q-values.The losses of an element is proportional to the square root of the resistivity and inversely proportional to the diameter. The measurements are made at the same frequency and therefore the element lengths are slightly different depending on the element diameters and it is not self evident in what way the small differences in length affect the losses. Neither in free space, nor inside a box. The losses of the box will affect the Q-value more for an element with high Q than for one with low Q. The coupling between the box and the element depends on the element diameter in a way that we do not know how to compute from theory. Without any good theoretical justification we adopted a simple model for the Q-value of an element in either of the two boxes. The model and our measured data can be found in this C-program qvbox.c (17452 bytes) The program gives us Q-values that match observations reasonably well and it expresses the losses of an element as its effective resistivity. Having copper, aluminium and brass elements with known resistivities among the measured data that the model is fitted to inside two different boxes gives us some confidence in the reliability of the results despite the lack of theory for the model. Table 4 shows a printout from qvbox.c. The reference elements 0 to 20 are fitted with a RMS error in the Q-value of 96 (QTbox-Qexp) Without any change of the model the resistivities of the other elements are fitted to make the model give the correct Q-values. The procedure is not quite correct because the degradation of Q due to the influence of a boom tube can not be represented by a resistivity that is the same for all diameters. The effect of a boom tube is slightly more harmful on thick elements than indicated by the resistivities that come out from the model. |

no material alloy diam le QTfree QTbox rat Qfree Qexp 0 Cu, massive 5011 3.98 320.73 6723 5589 1.203 6884 5723 1 Cu, massive 5011 5.95 315.28 10050 7627 1.318 10202 7743 2 Cu, massive 5011 7.97 310.61 13462 9379 1.435 13414 9345 3 Cu, massive 5011 9.94 307.53 16790 10830 1.550 16743 10800 4 Al, massive 6082 3.88 320.62 4738 3981 1.190 4856 4081 5 Al, massive 6082 5.95 315.24 7250 5582 1.299 7144 5500 6 Al, tube 6063 8.14 309.92 10242 7207 1.421 10157 7147 7 Al, tube 6063 10.07 307.16 12676 8312 1.525 12689 8320 8 Al, tube 6063 15.93 297.43 20049 10897 1.840 20608 11200 9 Brass 5.04 317.43 4136 3464 1.194 4223 3537 10 Brass 14.95 299.71 12254 7715 1.588 12013 7563 11 Al, tube 6063 10.14 307.19 12758 8346 1.529 12521 8191 12 Al, tube 6063 9.98 307.16 12557 8261 1.520 12388 8150 13 Al, tube 6063 10.07 307.13 12664 8306 1.525 12646 8295 14 Al, massive 6082 3.90 320.70 4750 3990 1.191 4878 4097 15 Al, massive 6082 5.95 315.25 7256 5585 1.299 7106 5470 16 Cu, massive 5011 10.00 307.59 16891 10871 1.554 16749 10780 17 Al, massive 6082 4.00 320.70 4878 4078 1.196 4820 4030 18 Al, massive 6082 6.00 315.25 7317 5621 1.302 7140 5485 19 Al, tube 6063 10.00 307.19 12582 8272 1.521 12645 8313 20 Al, tube 6063 10.00 307.13 12582 8272 1.521 12701 8350 21 Al, elox 15 um 10.11 307.19 11825 7845 1.507 11794 7825 22 Al, elox 15 um 3.88 320.67 4540 3828 1.186 4635 3908 23 Al, elox 15 um 5.89 315.15 6898 5347 1.290 6857 5315 24 Al, elox 30 um 10.14 307.08 11462 7647 1.499 11486 7663 25 Al, elox 30 um 3.88 320.48 4392 3712 1.183 4434 3748 26 Al, elox 30 um 5.91 315.14 6675 5194 1.285 6612 5145 27 Al, Paint 100 um 10.07 306.06 8601 6112 1.407 8826 6272 28 Al, Paint 100 um 3.91 317.78 3338 2894 1.153 3490 3026 29 Al, Paint 100 um 6.04 312.72 5161 4157 1.241 4774 3846 30 CO1(corroded Al) 9.86 307.10 11868 7900 1.502 11868 7900 31 CO2(corroded Al) 9.60 307.40 7614 5576 1.366 7614 5576 32 CO3(corroded Al) 8.03 310.20 8087 5926 1.365 8087 5926 33 Thru boom, glue 4.00 325.56 3456 2983 1.159 3818 3295 34 Thru boom, glue 6.00 320.85 5184 4175 1.242 5619 4525 35 Thru boom, glue 10.00 313.46 8641 6137 1.408 8025 5700 36 Thru boom, Starlock 4.00 326.27 1863 1703 1.094 2319 2120 37 Thru boom, Starlock 6.00 320.85 2794 2447 1.142 3282 2875 38 Thru boom, Starlock 10.00 313.58 4657 3763 1.238 4022 3250 39 Above boom 6.00 319.77 5668 4505 1.258 5545 4407 40 Above boom 10.00 311.04 9447 6577 1.436 9553 6651Table 4. Q-values inside a box and associated Q-values of the element itself. The Q-values inside the box (QTbox) are fitted to measurements. |

|

The result of the fitting procedure is that a high Q element like a 16 mm diameter aluminium tube has a Q-value inside the box that is 1.84 times lower than the Q-value of the element itself due to the losses of the box. An ordinary element such as a 6 mm aluminium rod is a factor 1.299 lower while a lossy element like a 5 mm brass rod has a Q-value that is reduced by only a factor of 1.194 by the box. The factors depend slightly on the diameters. The resistivities associated with table 4 are listed in table 5. |

Element type Resistivity

(ohm-cm)

Cu, massive (5011) 1.72

Al, massive (6082) 3.3

Al, tube (6063) 3.1

Brass 7.3

Al, elox 15 um 3.6

Al, elox 30 um 3.8

Al, Paint 100 um 6.7

CO1(corroded Al) 3.4

CO2(corroded Al) 7.8

CO3(corroded Al) 4.8

Thru boom, glue 6.6

Thru boom, Starlock 22.6

Above boom 5.5

Table 5. Losses of elements expressed

as resistivities.

|

|

An inspection of table 5 shows that mounting an element above the boom increases the losses by about 30% for a gain loss in the order of 0.1 dB and a S/N loss in the order of 0.5 dB in a low noise system. (Losses are proportional to the square root of the resistivity.) Insulated through-hole mounting with Starlock washers increases the losses by a factor of 2.6 with an associated gain loss in the order of 1 dB for a low loss yagi design. If one feeds 1 kW of 432 MHz power into a through hole mounted yagi with Starlock washers one should expect the boom tube to become warm because it would be heated from the washers by several hundred watts. An antenna with the elements above the boom tube - even if they are directly on the tube in electrical contact should remain cold. Anodizing with 15u changes the intrinsic Q of a 10 mm element to 11794 from a typical value around 12700 which means that the losses of the element have increased by 7%. The investigation presented on this page allows the following conclusions for the design of antennas in the 400 to 500 MHz region:

|